Anatomy of a Tyre

Hartex's Technological Marvel

How Hartex Betters Every Riding Experience

Hartex keeps the science of cycling in mind to consciously design low rolling resistance tyres that are speedier and tire you less. Easy cornering brings superior handling. Robust builds offer mastery over any terrain, so you experience crossing boundaries, not just riding a bike.

Facilities At Hartex

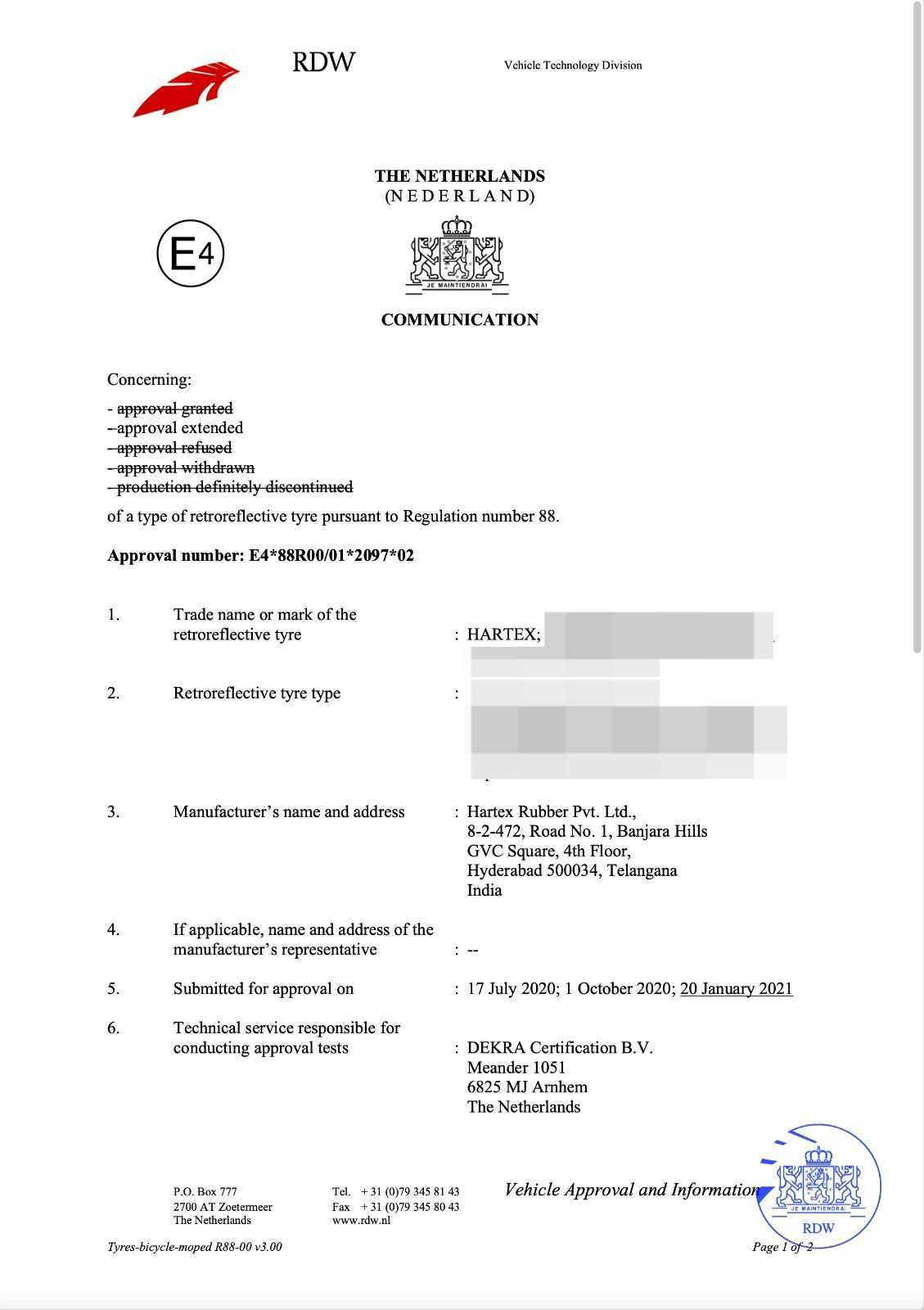

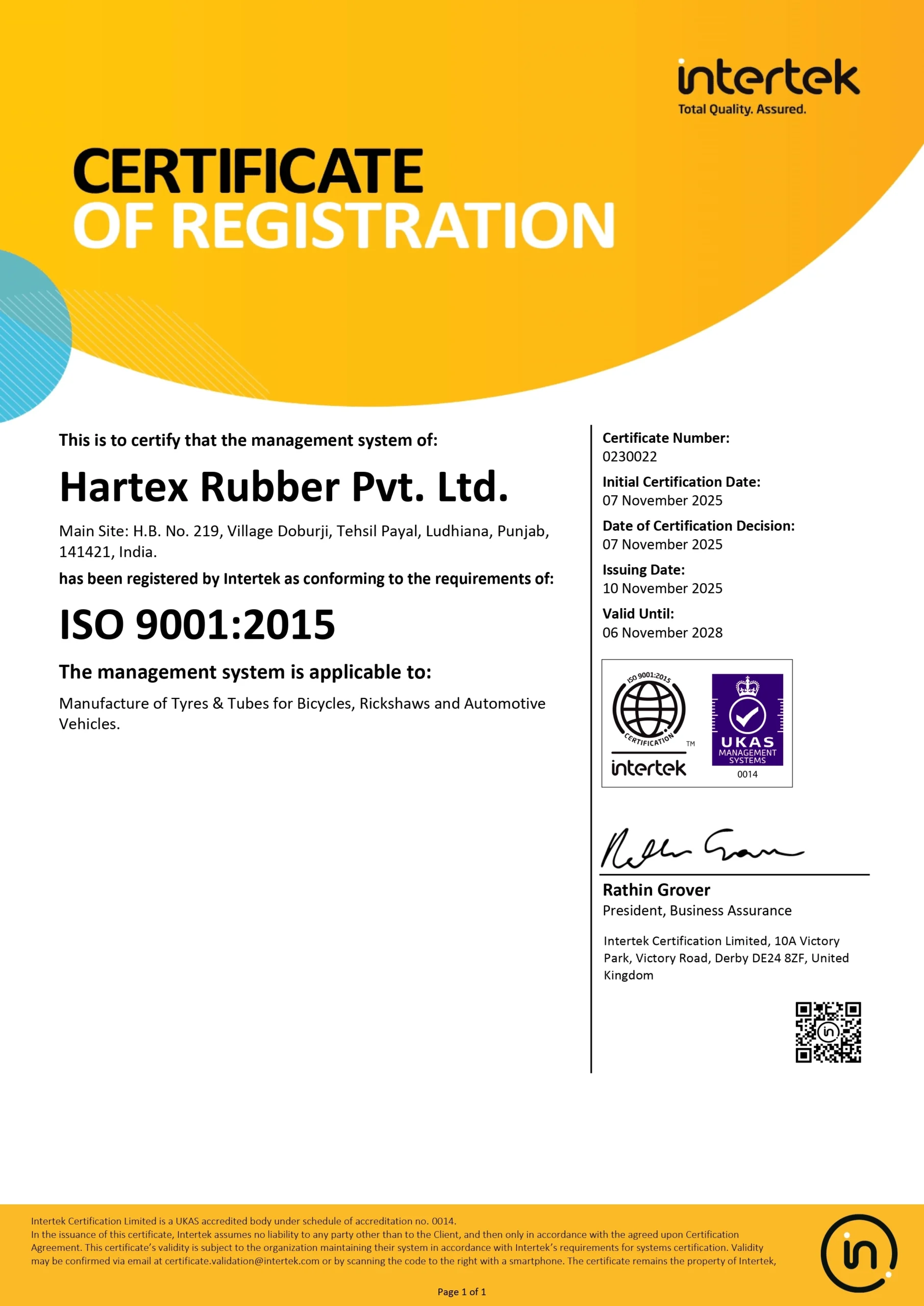

Established in 1987, the Hartex manufacturing plant in Hyderabad has been pivotal to our growth and success. Spanning across 7acres, this facility has become a cornerstone of our operations, producing 12 million bicycle tires, 12 million bicycle tubes annually. Employing over approximately 1100-1200 dedicated professionals, the Hyderabad plant is a powerhouse of tire and tube production, known for its consistent focus on quality, efficiency, and innovation.

The Hyderabad facility’s strategic location and advanced manufacturing processes enable Hartex to produce high-performance tires and tubes that cater to cyclists across the globe. Our commitment to stringent quality control measures ensures that every product manufactured here meets the highest international standards, solidifying our reputation for reliability and durability in the industry

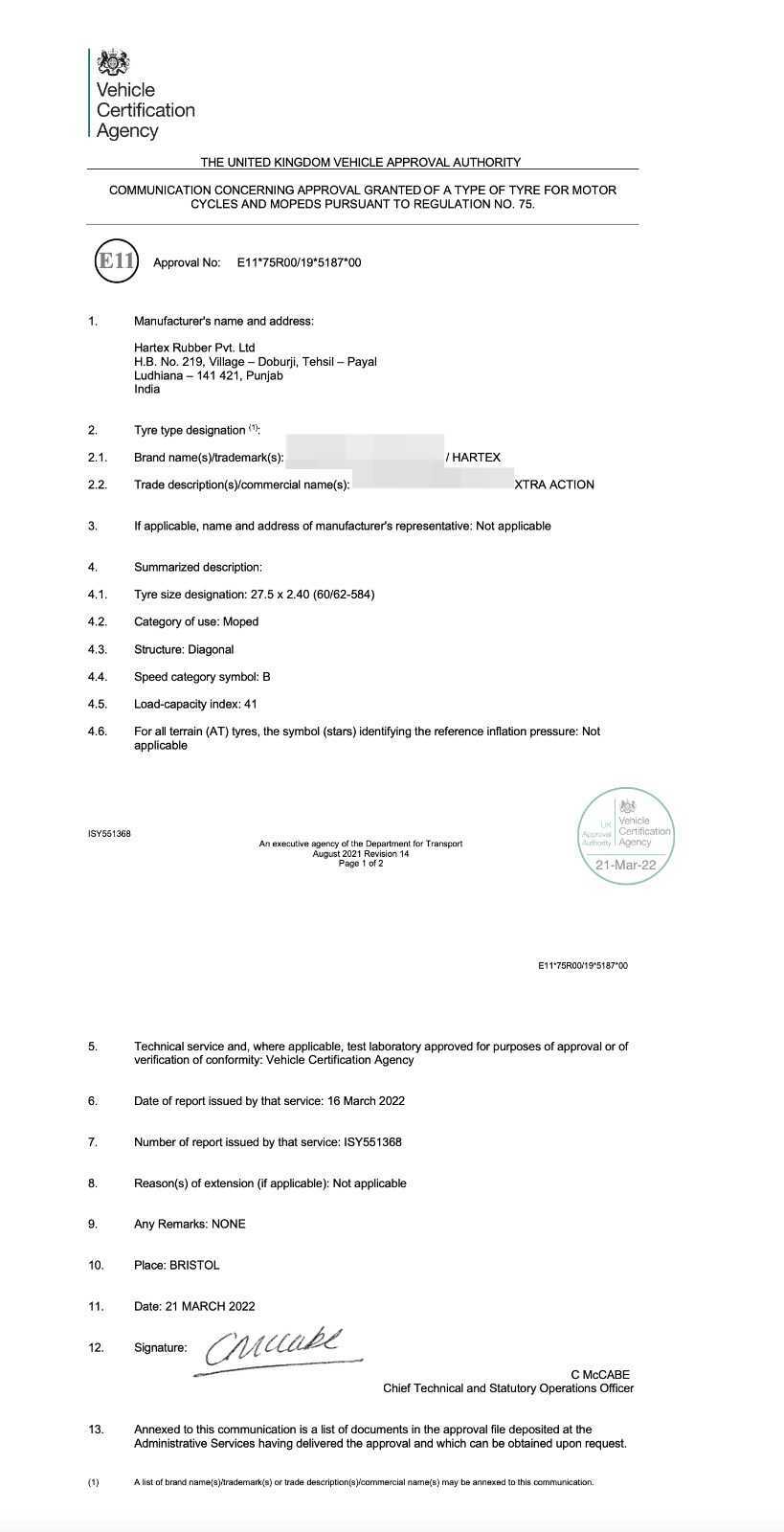

Expanding our capabilities to meet increasing demand, Hartex established its second manufacturing plant in Ludhiana in 2018. Like the Hyderabad facility, the Ludhiana plant covers 26 acres and boasts an annual production capacity of 8.5 million bicycle tires, 24 million bicycle tubes, 600k 2W tires per year and growing. With around 1300-1500 highly skilled employees, this plant represents Hartex’s dedication to adopting the latest technology and optimizing production processes for efficiency.

The Ludhiana facility is designed to incorporate state-of-the-art machinery and best-in-class manufacturing practices, ensuring the production of world-class tires and tubes that provide superior performance, grip, and durability. The plant’s modern infrastructure allows us to continue expanding our global footprint while upholding the company’s commitment to quality and innovation.

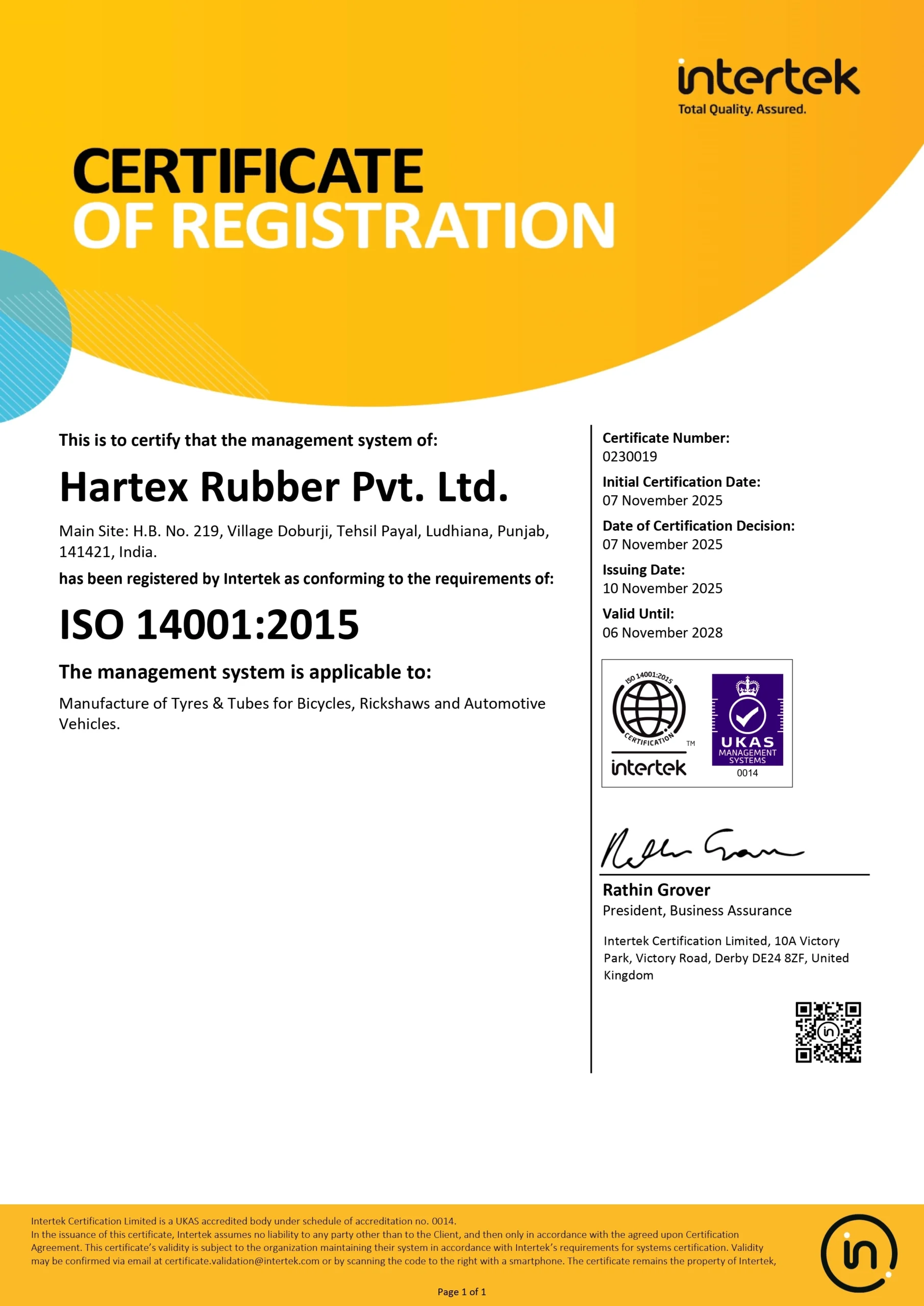

Innovating for a Sustainable Future

We’ve installed an advanced nitrogen generation system that saves 1,047.6 tons of steam and reduces 552 tons of CO2 emissions per year. Our mold maintenance utilizes dry ice blasting, eliminating harmful chemicals and saving 84 tons of water annually.

With a production capacity of 18 million bicycle tyres and 30 million tubes per year, Hartex leads the industry in sustainable manufacturing. Our R&D teams continually push for innovations that enhance both product performance and environmental responsibility, ensuring that every product contributes to a greener future.