Hartex

Types of Tyres

Bicycle tires come in a variety of types, each designed to suit a particular style of riding or type of bicycle. Here are some of the most common types:

- Clincher Tires: These are the most common type of tire and feature a bead that hooks onto the inside of the wheel rim. Clincher tires can be used with an inner tube or set up tubeless with a liquid sealant.

- Tubeless Tires: Tubeless tires don't use an inner tube and instead form an airtight seal against the rim. They're often filled with a liquid sealant that can automatically seal small punctures. Tubeless tires can provide better puncture resistance and allow you to ride at lower tire pressures for better traction and comfort.

- Tubular Tires: Also known as "sew-up" tires, tubular tires feature an inner tube that's fully encased within the tire. The whole tire is then glued onto a specific type of rim. Tubular tires are most commonly used in high-performance and racing scenarios due to their excellent ride feel and performance characteristics, but they can be more difficult to install and repair than other types of tires.

- Semi-Slick Tires: Semi-slick tires have a smooth center for low rolling resistance on straightaways, with treads on the edges for cornering grip. They're often used for city riding or cyclocross.

- Slick Tires: Slick tires are smooth and are designed for optimal speed and traction on paved roads. They're most commonly used on road bikes

- Mountain Bike (MTB) Tires:MTB tires have large, knobby treads for maximum grip on off-road trails. They come in a variety of widths, with wider tires providing more grip and shock absorption. MTB tires can be clincher, tubeless, or tubular.

- Fat Bike Tires: Fat bike tires are extremely wide (often 4" or more) and are designed for riding on loose, soft surfaces like snow and sand. They provide excellent traction and stability in these conditions.

- Gravel Tires: Gravel tires are a middle-ground between road and mountain bike tires. They're designed to perform well on a variety of surfaces, from smooth pavement to rough gravel and dirt roads.

- Hybrid/Commuter Tires: Hybrid or commuter tires are designed for comfort and durability. They typically have moderate tread for good grip in a variety of weather conditions and are made to withstand the rigors of daily commuting.

These are just a few examples of the variety of tire types. The right type for you will depend on your bike and the type of riding you plan to do. At Hartex Rubber, we offer a wide range of tire types to suit every kind of cyclist, from casual commuters to dedicated racers.

What are Directional tires?

Directional tires, also known as asymmetric tires, are specifically designed to roll in one direction. They have a tread pattern that is intended to perform optimally when the tire is mounted to rotate a specific way.

The tread pattern on directional tires is usually V-shaped or arrow-shaped, and is engineered to channel water out from under the tire in wet conditions, reducing the risk of hydroplaning. This pattern also often helps to reduce road noise for a quieter ride and provides improved stability and traction at higher speeds or during cornering.

On the sidewall of a directional tire, you’ll see an arrow or other marking that indicates the direction the tire should rotate when the bike is moving forward. When mounting directional tires, it’s important to ensure they’re installed to rotate in the correct direction.

Directional tires are common in performance-oriented scenarios, such as racing or aggressive mountain biking, where the optimized tread pattern can provide a noticeable performance benefit.

However, one drawback to consider is that directional tires can only be rotated front-to-rear (if the bike’s wheels are the same size), and not left-to-right or vice versa, which can limit your tire rotation options compared to non-directional tires.

At Hartex Rubber, our range of products includes directional tires that are engineered with high-quality materials and advanced tread designs, providing you with improved safety and performance on the road or trail.

Hartex

Technology

Hartex with its experience in the manufacturing of bicycle tyres and tubes for more than 5 decades has developed products to meet the changing and stringent requirements of the customers across the globe.

With the state of the art plant at Ludhiana, India, Hartex is equipped to manufacture world class products with consistency to meet any international standard or customer requirements.

What is a bicycle tyre?

A tyre (tire in American English) is a torroidal / ring shaped component that covers the rims of the bicycle and transfers the load of the bike and rider to the ground to provide traction. They can be pneumatic or solid in type. Mostly pneumatic tyres are used in bicycles for better riding comfort. Pneumatic tyres can be either tubular or tubeless.

A tyre that needs a tube for holding air is called Tubular tyre. If the air can be held without tubes then it is called as Tubeless tyre.

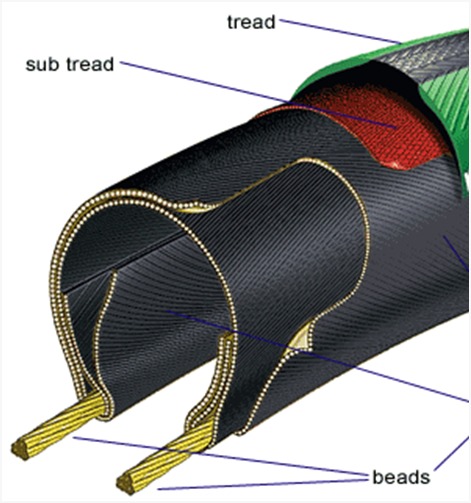

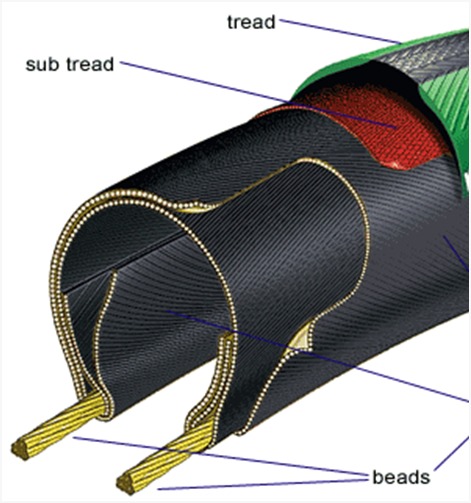

A tyre consists of the following components

Tread

The outer layer of the tyre made of rubber compound that surrounds the casing and bead rings. The function of the tyre is to grip the surface, convert the pedalling power to vehicle movement, protect the casing and absorb the shock while riding.

Tread portion that touches is the ground consists of tread patterns which are designed to meet the service conditions such as racing, city road, off-road.

The tread component that extends to the side of the tyre is called as Sidewall. If the sidewall is made of rubber compound then the tyres are called as Gum-wall tyres.

If there is no rubber tread on the sidewall, the tyres are called as Skin-wall tyres

A sub tread made of rubberized textile or special cushion rubber compound is used in Puncture resistance tyres.

Casing

Casing is the skeleton of the tyre which gives the proper shape to the tyre and it carries the load.

It consists of rubberized textile usually nylon.

The density of the textile is measured in TPI (threads per inch) which is designed as per the needed performance of the tyre.

Number of textile layers can be 2 or 4 depending upon the service requirements

Beads

Beads are bands of high tensile material in rubber compound. Beads are stronger and inelastic. They provide the mechanical strength to fit the tyre to the rim and hold on to it.

Wired tyres –A rigid wire, usually copper / bronze coated steel wire is used for bead

Foldable tyres – A strong but foldable bead usually made of aramid fibres (Kevlar) is used for bead.

Aramid beads are stronger but they are lighter by about 50 – 90 grams compared to wired tyres.

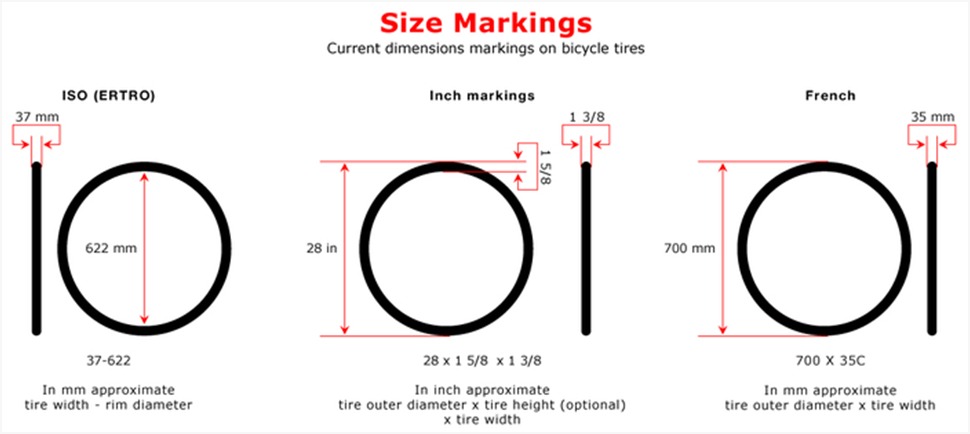

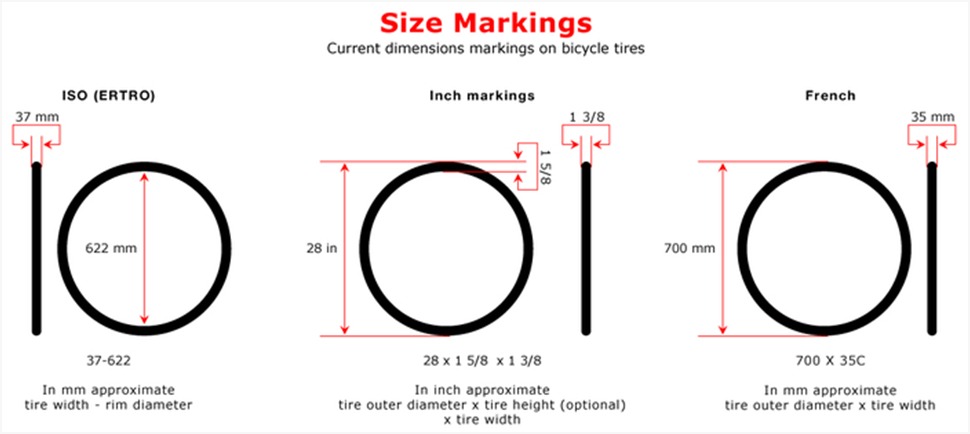

Tyre Dimensions

What are the factors that impact tyre performance?

- The nature and quality of the rubber compound

- Tread pattern design

- Construction of casing - textile type (Nylon/Cotton/Polyester) and TPI

- Tyre Engineering such as tyre contour, number of layers of textiles, bead wire construction and gauges

- Tyre rolling resistance – depends on all the above

- Type & quality of the inner rubber tube

- Surface of ride

Hartex High Performance Products

MAXIGRIP

One of the critical components of the tyre is rubber compound and Hartex has designed a superior compound for higher performance with Maxi Grip technology.

The key properties of tyres for higher performance are

- Higher Static friction for better grip

- Lower rolling resistance for easy riding &

- Softer compound for comfort

- Higher abrasion resistance for better life

But these properties move in different or rather opposite directions. For example,if the grip is increased, the rolling resistance also increases where higher effort needed to ride. If the compound is made softer for absorbing shock better, the abrasion resistance decreases leading to poor life of the tyre.

Hartex Research & Developmentwing has developed “Maxigrip”compound with a unique blend of polymers with select fillers& chemicals for high performance.

In combination with contour of the tyre and the pattern on the tyre surface, Hartex tyres are designed for superior performance.

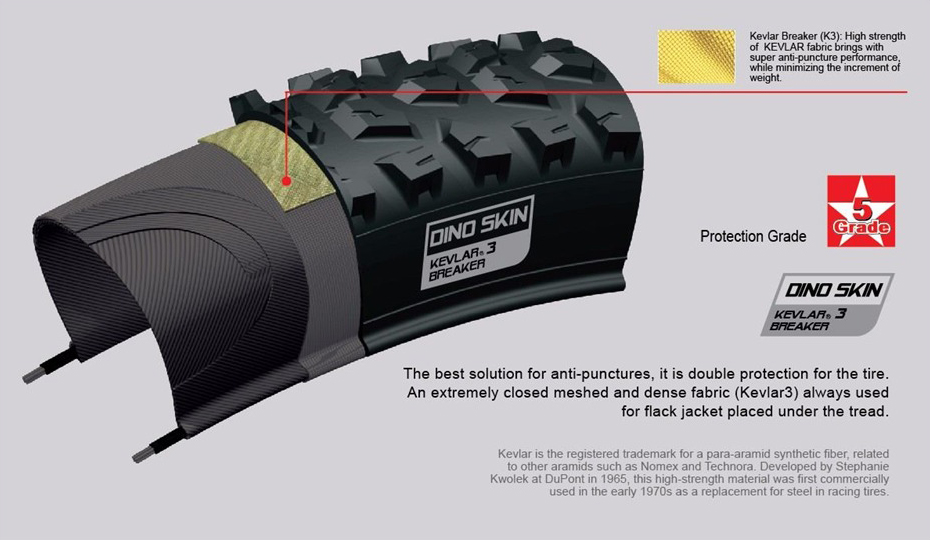

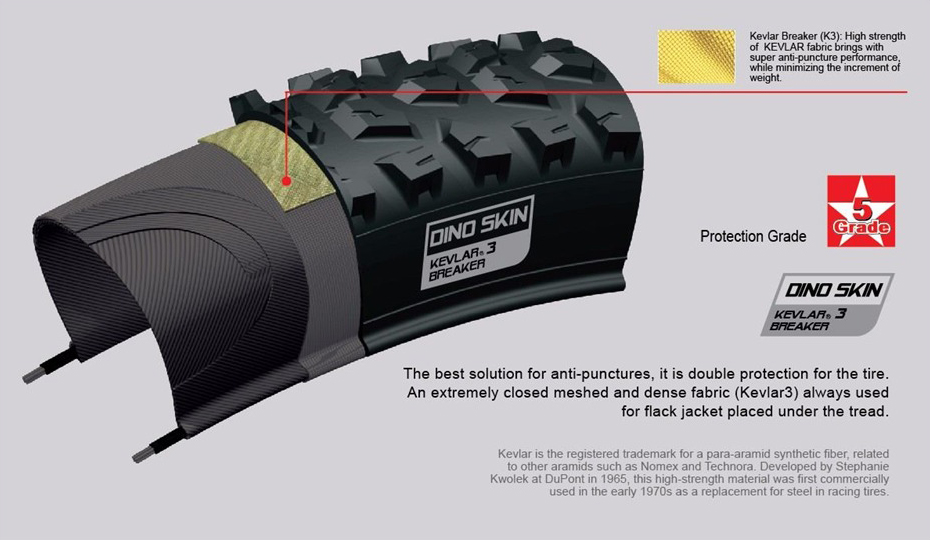

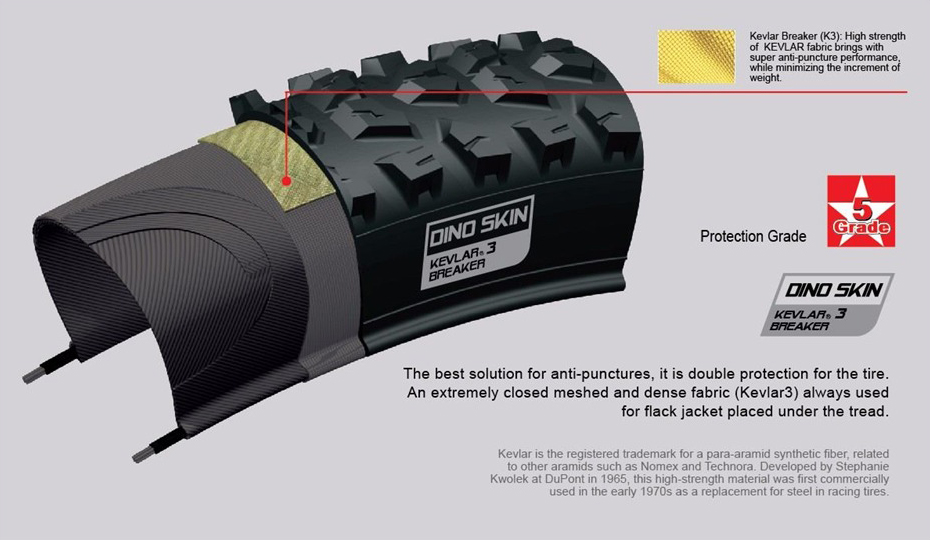

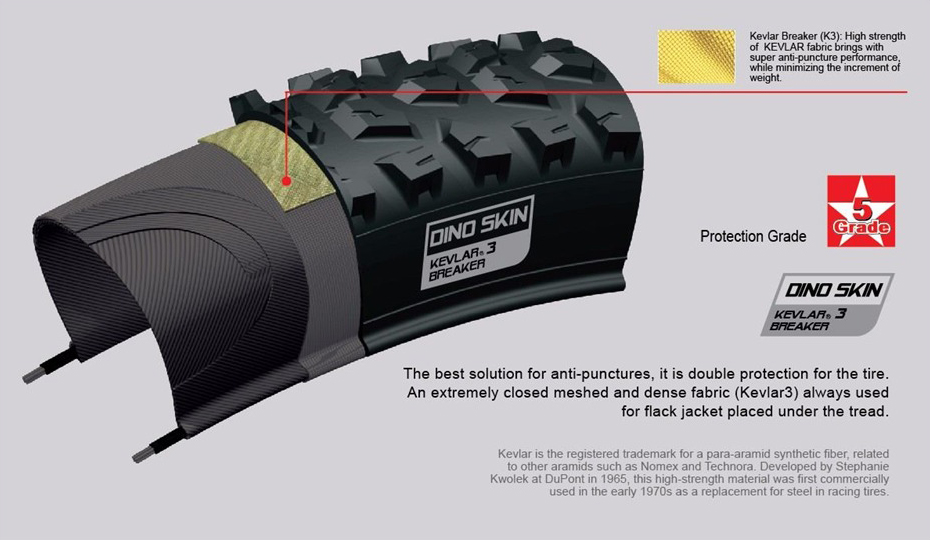

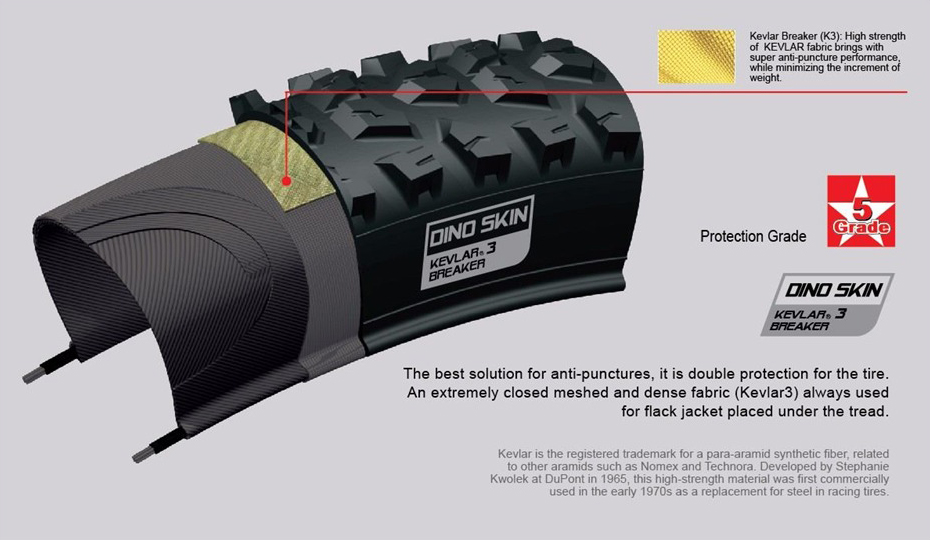

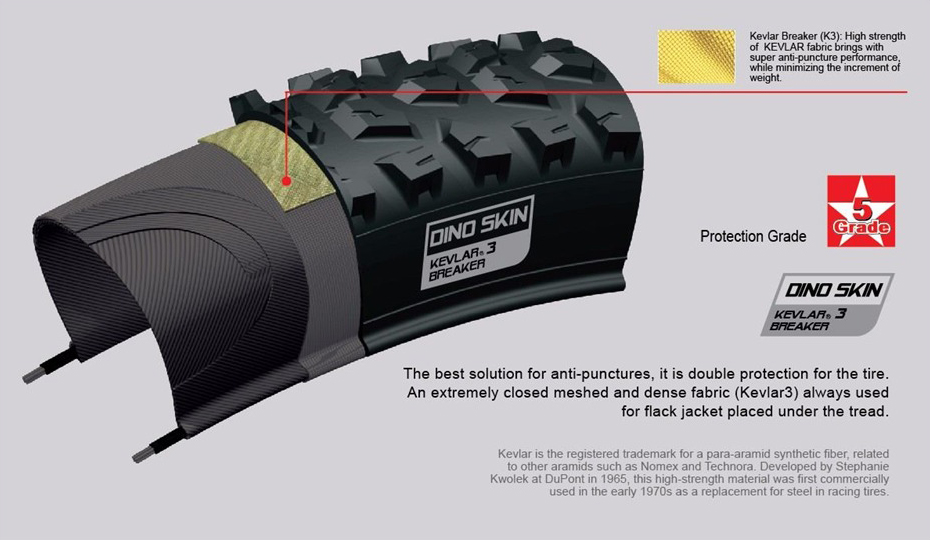

Puncture Resistance Tyres PunctureGuard

Puncture during riding is an annoying situation and kills the pleasure of riding a bike. We manufacture puncture resistant tyres using any one or combination of the following technologies:

- Quality of the rubber compound and its gauge

- Additional layers of textile below the tread pattern

- Higher textile density of up to 60TPI

- Protective Rubber Belt – containing highly elastic rubber below the tread

Hartex High Performance Products

Tubeless Tires

Chafer Materials

Casing Fabric

Skin wall Tyres

Tire Bead Types

Foldable tyres are made with aramid fibres (Kevlar) which are stronger than steel but lighter. The weight of the tyres can be lower by around 50 to 90 grams depending upon the tyre size and type.

Breaker Layers

Different Configurations of Hartex Tyres

Multi-compound tires

Label Application

Tyres with reflective tapes

Coloured Tires

Size Range Possible

TUBES