Hartex

Types of Tyres

Bicycle tires come in a variety of types, each designed to suit a particular style of riding or type of bicycle. Here are some of the most common types:

- Clincher Tires: These are the most common type of tire and feature a bead that hooks onto the inside of the wheel rim. Clincher tires can be used with an inner tube or set up tubeless with a liquid sealant.

- Tubeless Tires: Tubeless tires don't use an inner tube and instead form an airtight seal against the rim. They're often filled with a liquid sealant that can automatically seal small punctures. Tubeless tires can provide better puncture resistance and allow you to ride at lower tire pressures for better traction and comfort.

- Tubular Tires: Also known as "sew-up" tires, tubular tires feature an inner tube that's fully encased within the tire. The whole tire is then glued onto a specific type of rim. Tubular tires are most commonly used in high-performance and racing scenarios due to their excellent ride feel and performance characteristics, but they can be more difficult to install and repair than other types of tires.

- Semi-Slick Tires: Semi-slick tires have a smooth center for low rolling resistance on straightaways, with treads on the edges for cornering grip. They're often used for city riding or cyclocross.

- Slick Tires: Slick tires are smooth and are designed for optimal speed and traction on paved roads. They're most commonly used on road bikes

- Mountain Bike (MTB) Tires:MTB tires have large, knobby treads for maximum grip on off-road trails. They come in a variety of widths, with wider tires providing more grip and shock absorption. MTB tires can be clincher, tubeless, or tubular.

- Fat Bike Tires: Fat bike tires are extremely wide (often 4" or more) and are designed for riding on loose, soft surfaces like snow and sand. They provide excellent traction and stability in these conditions.

- Gravel Tires: Gravel tires are a middle-ground between road and mountain bike tires. They're designed to perform well on a variety of surfaces, from smooth pavement to rough gravel and dirt roads.

- Hybrid/Commuter Tires: Hybrid or commuter tires are designed for comfort and durability. They typically have moderate tread for good grip in a variety of weather conditions and are made to withstand the rigors of daily commuting.

These are just a few examples of the variety of tire types. The right type for you will depend on your bike and the type of riding you plan to do. At Hartex Rubber, we offer a wide range of tire types to suit every kind of cyclist, from casual commuters to dedicated racers.

What are Directional tires?

Directional tires, also known as asymmetric tires, are specifically designed to roll in one direction. They have a tread pattern that is intended to perform optimally when the tire is mounted to rotate a specific way.

The tread pattern on directional tires is usually V-shaped or arrow-shaped, and is engineered to channel water out from under the tire in wet conditions, reducing the risk of hydroplaning. This pattern also often helps to reduce road noise for a quieter ride and provides improved stability and traction at higher speeds or during cornering.

On the sidewall of a directional tire, you’ll see an arrow or other marking that indicates the direction the tire should rotate when the bike is moving forward. When mounting directional tires, it’s important to ensure they’re installed to rotate in the correct direction.

Directional tires are common in performance-oriented scenarios, such as racing or aggressive mountain biking, where the optimized tread pattern can provide a noticeable performance benefit.

However, one drawback to consider is that directional tires can only be rotated front-to-rear (if the bike’s wheels are the same size), and not left-to-right or vice versa, which can limit your tire rotation options compared to non-directional tires.

At Hartex Rubber, our range of products includes directional tires that are engineered with high-quality materials and advanced tread designs, providing you with improved safety and performance on the road or trail.

Hartex

Technology

Hartex with its experience in the manufacturing of bicycle tyres and tubes for more than 5 decades has developed products to meet the changing and stringent requirements of the customers across the globe.

With the state of the art plant at Ludhiana, India, Hartex is equipped to manufacture world class products with consistency to meet any international standard or customer requirements.

What is a bicycle tyre?

A tyre (tire in American English) is a torroidal / ring shaped component that covers the rims of the bicycle and transfers the load of the bike and rider to the ground to provide traction. They can be pneumatic or solid in type. Mostly pneumatic tyres are used in bicycles for better riding comfort. Pneumatic tyres can be either tubular or tubeless.

A tyre that needs a tube for holding air is called Tubular tyre. If the air can be held without tubes then it is called as Tubeless tyre.

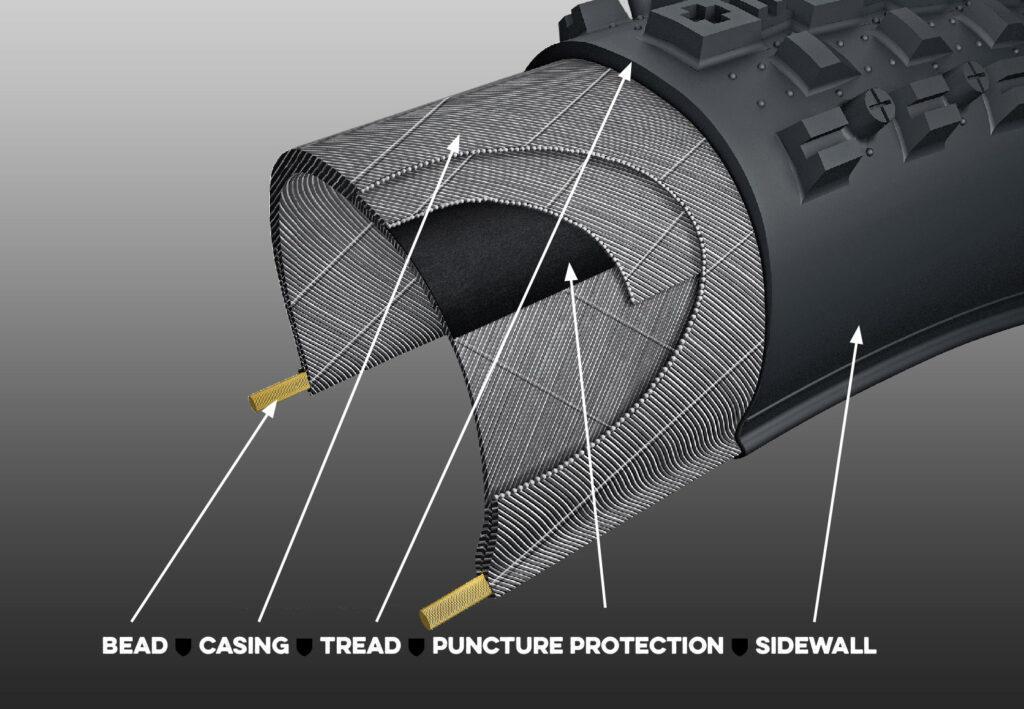

A tyre consists of the following components

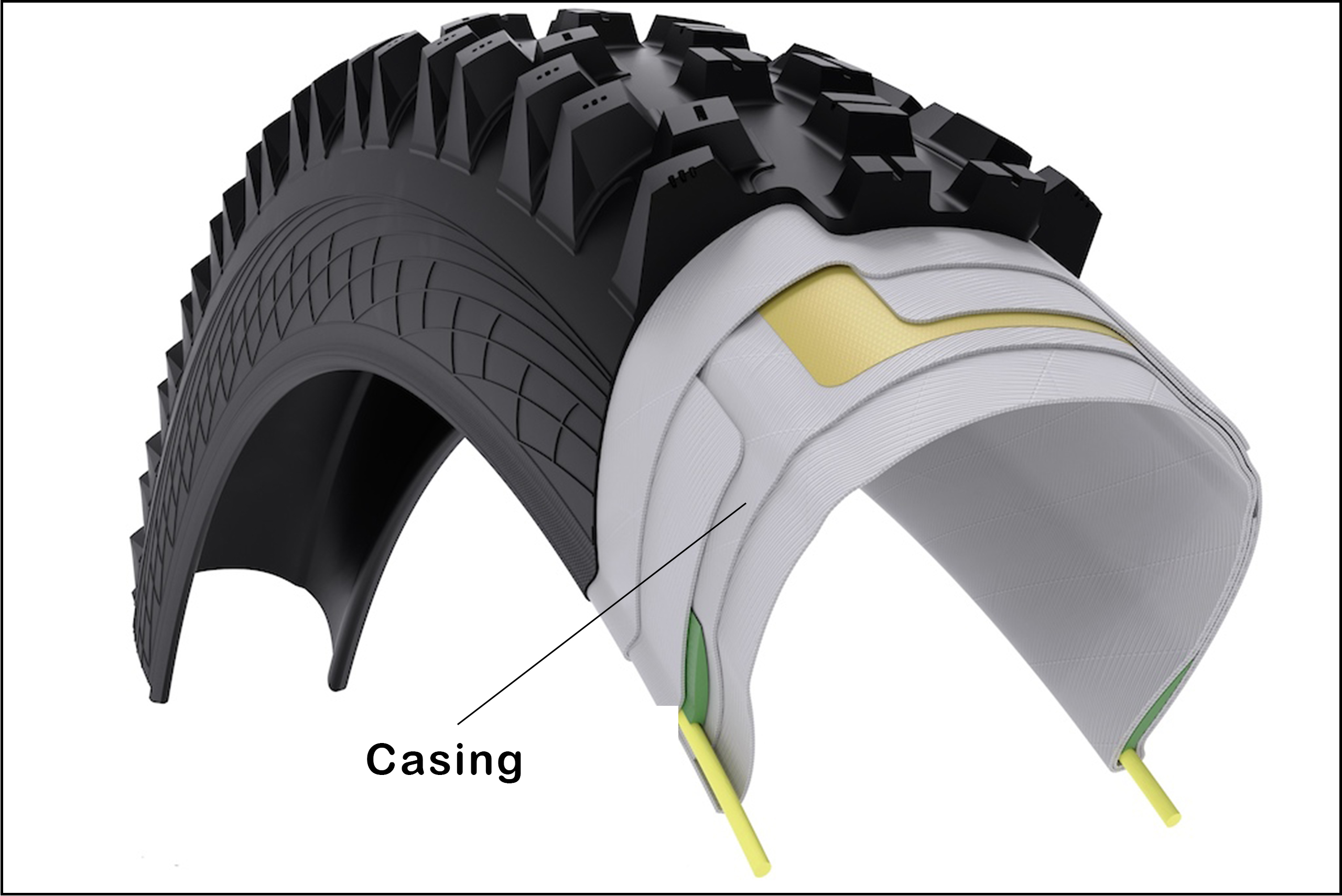

Casing

Casing is the skeleton of the tyre which gives the proper shape to the tyre and it carries the load.

It consists of rubberized textile usually nylon.

The density of the textile is measured in TPI (threads per inch) which is designed as per the needed performance of the tyre.

Number of textile layers can be 2 or 4 depending upon the service requirements

Tread

The outer layer of the tyre made of rubber compound that surrounds the casing and bead rings. The function of the tyre is to grip the surface, convert the pedalling power to vehicle movement, protect the casing and absorb the shock while riding.

Tread portion that touches is the ground consists of tread patterns which are designed to meet the service conditions such as racing, city road, off-road.

The tread component that extends to the side of the tyre is called as Sidewall. If the sidewall is made of rubber compound then the tyres are called as Gum-wall tyres.

If there is no rubber tread on the sidewall, the tyres are called as Skin-wall tyres

A sub tread made of rubberized textile or special cushion rubber compound is used in Puncture resistance tyres.

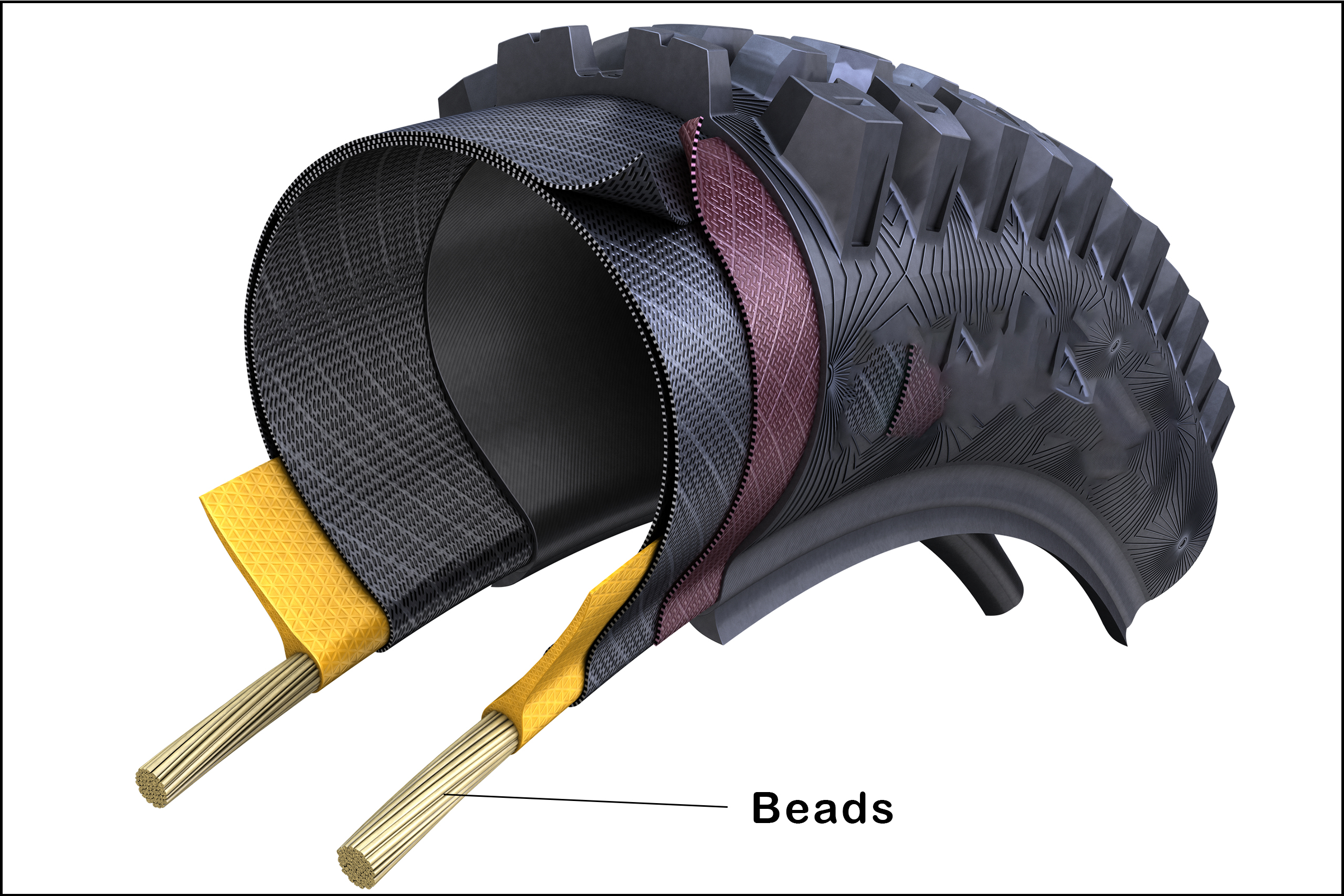

Beads

Beads are bands of high tensile material in rubber compound. Beads are stronger and inelastic. They provide the mechanical strength to fit the tyre to the rim and hold on to it.

Wired tyres –A rigid wire, usually copper / bronze coated steel wire is used for bead

Foldable tyres – A strong but foldable bead usually made of aramid fibres (Kevlar) is used for bead.

Aramid beads are stronger but they are lighter by about 50 – 90 grams compared to wired tyres.

Tyre Dimensions

What are the factors that impact tyre performance?

- The nature and quality of the rubber compound

- Tread pattern design

- Construction of casing - textile type (Nylon/Cotton/Polyester) and TPI

- Tyre Engineering such as tyre contour, number of layers of textiles, bead wire construction and gauges

- Tyre rolling resistance – depends on all the above

- Type & quality of the inner rubber tube

- Surface of ride

Hartex High Performance Products

MAXIGRIP

One of the critical components of the tyre is rubber compound and Hartex has designed a superior compound for higher performance with Maxi Grip technology.

The key properties of tyres for higher performance are

- Higher Static friction for better grip

- Lower rolling resistance for easy riding &

- Softer compound for comfort

- Higher abrasion resistance for better life

But these properties move in different or rather opposite directions. For example,if the grip is increased, the rolling resistance also increases where higher effort needed to ride. If the compound is made softer for absorbing shock better, the abrasion resistance decreases leading to poor life of the tyre.

Hartex Research & Developmentwing has developed “Maxigrip”compound with a unique blend of polymers with select fillers& chemicals for high performance.

In combination with contour of the tyre and the pattern on the tyre surface, Hartex tyres are designed for superior performance.

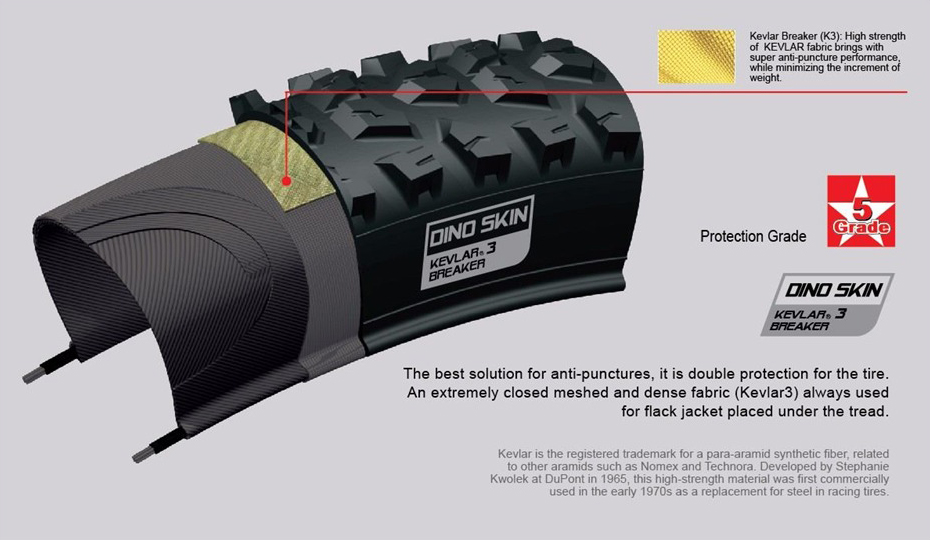

Puncture Resistance Tyres PunctureGuard

Puncture during riding is an annoying situation and kills the pleasure of riding a bike. We manufacture puncture resistant tyres using any one or combination of the following technologies:

- Quality of the rubber compound and its gauge

- Additional layers of textile below the tread pattern

- Higher textile density of up to 60TPI

- Protective Rubber Belt – containing highly elastic rubber below the tread

Hartex High Performance Products

Tubeless Tires

Chafer Materials

Casing Fabric

Skin wall Tyres

Tire Bead Types

Foldable tyres are made with aramid fibres (Kevlar) which are stronger than steel but lighter. The weight of the tyres can be lower by around 50 to 90 grams depending upon the tyre size and type.

Breaker Layers

Different Configurations of Hartex Tyres

Multi-compound tires

Label Application

Tyres with reflective tapes

Coloured Tires

Size Range Possible

TUBES

Multi-compound tires

Label Application

Tyres with reflective tapes

Coloured Tires

Size Range Possible

TUBES

Key Components of a Bicycle Inner Tube

A bicycle inner tube typically consists of:

This is the main part of the tube that inflates. It's made of a rubber or synthetic material that can expand and contract while maintaining air pressure.

This is the part of the tube that allows you to inflate or deflate it. The two most common types are Schrader (similar to those used on car tires) and Presta (narrower and used on many road bikes).

Types of Materials Used to Make Bicycle Tubes

- Natural Rubber: Natural rubber tubes have excellent elasticity, allowing them to handle the variations in tire pressure that come from hitting bumps in the road. However, they are less resistant to punctures and often lose air more quickly than other materials.

- Butyl Rubber: This synthetic rubber is the most commonly used material for bicycle tubes due to its excellent air retention and good puncture resistance. Butyl tubes are generally heavier than those made from other materials.

- Thermoplastic Polyurethane (TPU): TPU tubes are lightweight and resistant to punctures, but they don't retain air as well as butyl rubber tubes. They are often more expensive than butyl or natural rubber tubes.

- Latex: Latex tubes offer lower rolling resistance and are lighter than butyl rubber tubes, potentially making them a good choice for racing or performance-oriented riding. However, they don't hold air as long as butyl rubber tubes and need to be inflated more frequently.

Trade-offs Across These Types of Tubes

- Weight: Latex and TPU tubes are typically lighter than butyl or natural rubber tubes, which can be a benefit for performance-oriented riders.

- Puncture Resistance: Butyl rubber and TPU tubes typically offer better puncture resistance than natural rubber or latex tubes.

- Air Retention: Butyl rubber tubes hold air longer than latex or natural rubber tubes, meaning you'll need to inflate them less frequently.

- Rolling Resistance: Latex tubes are generally considered to have the lowest rolling resistance, which can make your ride feel smoother and potentially faster.

- Cost: Butyl rubber tubes are generally the least expensive, while TPU and latex tubes are usually more costly.

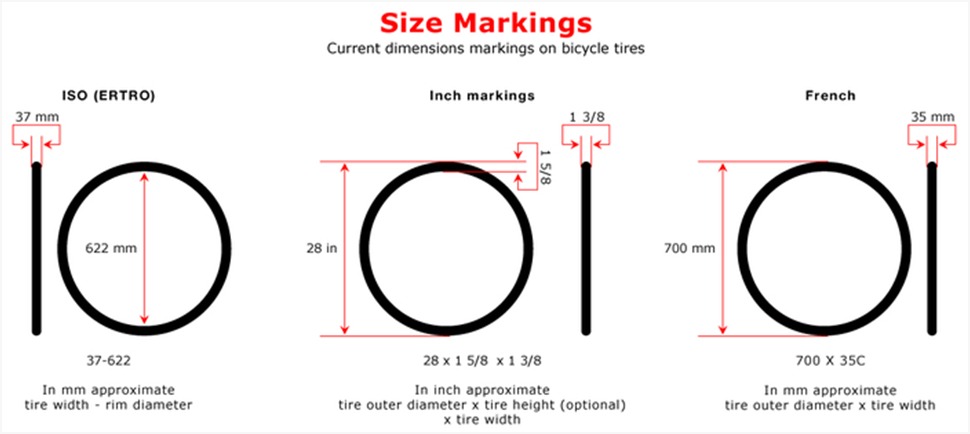

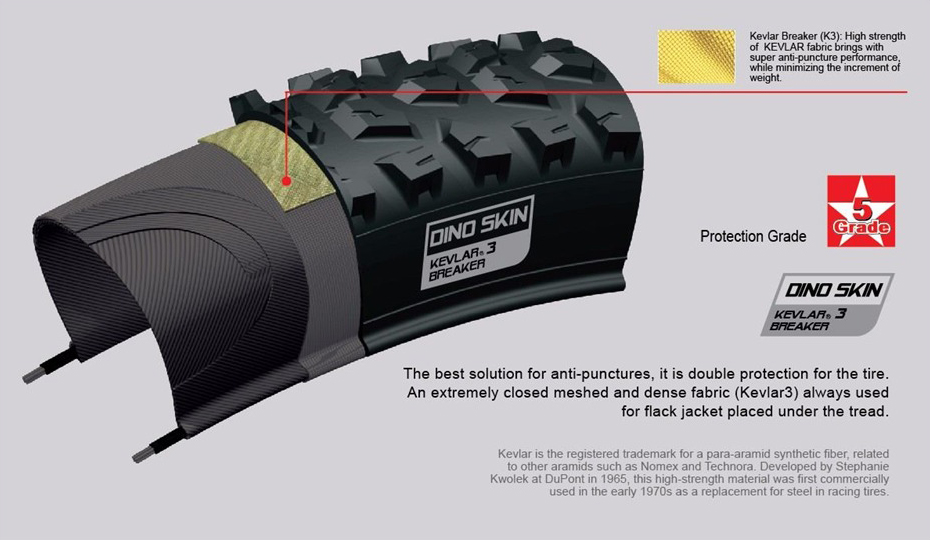

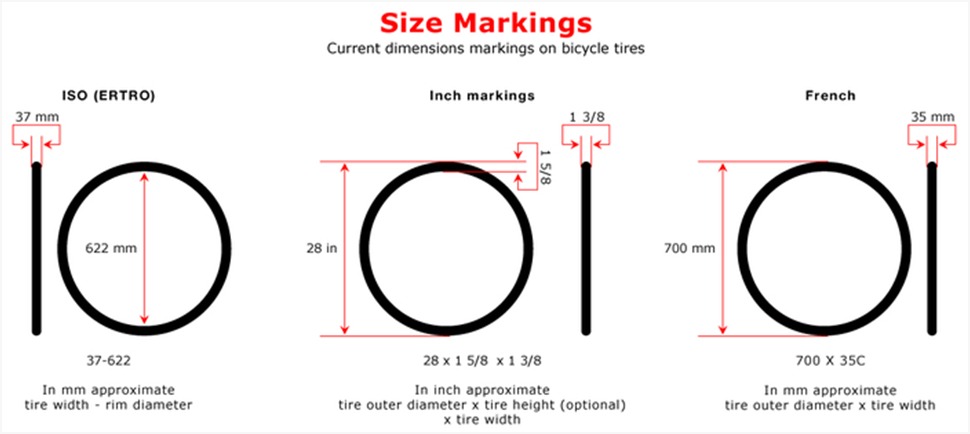

Understanding Bicycle Tire Size Systems

When it comes to bicycle tires, there are three main tire sizing systems that are used across the globe: the British (or Imperial), French, and the ETRTO (European Tyre and Rim Technical Organisation) systems. The differences between these systems lie in their units of measurement and the aspects of the tire they choose to measure.

- British System: The British system uses inches to denote the diameter of the tire. For example, a common mountain bike tire size would be written as 26 x 2.2, where the first number (26) represents the diameter of the tire in inches, and the second number (2.2) represents the width of the tire, also in inches.

- French System: The French system, also known as the metric system, uses millimeters to measure the width of the tire, while the diameter of the wheel is still expressed in inches. An example would be 700x23 where 700 is the outer diameter of the tire in millimeters, and 23 is the width of the tire in millimeters.

- ETRTO System: This system is becoming more widely used due to its precision and clarity. It expresses the width of the tire and the diameter of the wheel in millimeters. So, a tire size would be written as 37-622 where 37 is the width of the tire in millimeters and 622 is the diameter of the wheel's inner rim where the tire sits (also known as the bead seat diameter), also in millimeters.

Why Do 26", 27.5", and 29" Tires Have the Same ETRTO Diameter?

There is often a misconception about the ETRTO diameter of tires labeled as 26″, 27.5″, and 29″ in the British system. It’s important to note that these labels are approximate indications of the outside diameter of the tire when it’s mounted and inflated, not the precise bead seat diameter, which is what the ETRTO system measures.

Here’s a simplified explanation:

- 26" Tires: These are typically used on traditional mountain bikes. In the ETRTO system, a common bead seat diameter for a 26" tire is 559mm.

- 27.5" Tires (also labeled as 650B): These are a newer size used on some mountain bikes. Despite the larger British measurement, these tires share the same bead seat diameter (584mm) with some types of 26" tires known as 650B in the French system.

- 29" Tires (also labeled as 700C): Commonly used on road bikes, hybrids, and newer mountain bikes, these tires share the same bead seat diameter (622mm) as 28" tires. The '29"' label comes from the approximate outer diameter when a typical large-volume mountain bike tire is mounted and inflated on a 622mm bead seat diameter rim.

Why Do Some British System Sizes Have a Third Dimension?

In the British system, tire sizes are often presented with the diameter first, followed by the width. Sometimes, you may also encounter a third value which indicates the height or profile of the tire, given as a fraction. However, these are generally older, less commonly used tire sizes today.

Let's take an example of 26 x 1 3/8. Here:

- '26' is the approximate diameter of the wheel (including the tire) in inches.

- '1 3/8' is the width of the tire when it's inflated, also given in inches.

Now, here are some examples which might confuse users:

- 26 x 1.5 versus 26 x 1 1/2: These seem like they should be the same size, but they're not. The first is a more modern size where the width is given as a decimal, whereas the second is an older, fractional size. Although '1/2' and '0.5' are mathematically the same, the two sizes are not interchangeable.

- 27 x 1 1/4 versus 700 x 35C: These two sizes can also be confusing. The first tire is an older road bike size given in the British system, while the second is a modern road or hybrid tire size usually seen in the French or ETRTO systems. Despite being quite similar in actual size, the two are not interchangeable due to differences in the diameter of the rim they're designed to fit.

In conclusion, when choosing a tire size, it’s important to know not just the diameter and width of the tire, but also to pay attention to the specific sizing system being used, and whether the width is being given as a decimal or a fraction. Always double-check to ensure you’re getting a size that will fit your bike’s rims and meet your cycling needs.

At Hartex Rubber, we aim to simplify this process by providing clear, accurate sizing information for all our products, ensuring you get the right fit every time.

Size Translation Grid

Here’s a simple grid that translates a few common tire sizes across the British, French, and ETRTO systems:

|

British |

French(mm) |

ETRTO |

| 26 x 2.0 | 650B | 50-559 |

| 27.5 x 2.0 | 650B | 50-584 |

| 29 x 2.2 | 700C | 56-622 |

| 700 x 23C | 700 x 23 | 23-622 |

The ETRTO system, which is the most precise, lists the width of the tire first and then the diameter of the wheel’s inner rim where the tire sits (bead seat diameter).

Please note that these are approximate translations and it’s always best to check the specifications of your tire and wheel to ensure compatibility.

In the end, our primary objective at Hartex Rubber is to help you understand the different tire sizing systems, so you can make informed decisions about the best tires and inner tubes for your bicycle. We are dedicated to delivering the right product to meet your specific needs.

How are 28" and 29" tires different from each other? What is the advantage of the newer 27.5" and 29" sizes?

The terms “28-inch” and “29-inch” are used to represent approximate outside diameters of the tires when mounted and inflated on their respective rims. In the ETRTO system, both of these tire sizes typically have a bead seat diameter of 622mm, meaning they fit the same diameter rims.

However, the main difference between these two sizes comes from the type of bike they’re usually associated with, and consequently, the typical width and profile of the tires:

- 28-inch tires are traditionally used on touring bikes, city bikes, and some older road bikes. These tires are often narrower (e.g., 28-622 in ETRTO, equivalent to 700x28C in French) and designed for paved roads and light gravel paths.

- 29-inch tires, also labeled as 700C, are most commonly used on modern mountain bikes and some hybrids. These tires are typically wider (e.g., 56-622 in ETRTO, equivalent to 700x56C or 29x2.2 in British) and have treads optimized for off-road use.

Now, let’s discuss the advantages of the newer 27.5″ and 29″ sizes:

- 27.5-inch tires (650B): The 27.5" size offers a middle ground between the older 26" size and the larger 29" size. These tires can provide a better fit for smaller riders or those who prefer a bike that's a bit more maneuverable and nimble than a 29" but rolls better than a 26". They are also lighter and accelerate more quickly than their 29" counterparts.

- 29-inch tires: The main advantage of 29" tires is their ability to roll over obstacles more easily due to their larger diameter. They also provide better momentum once moving and increased contact area with the ground, which can result in better traction. However, they can feel a bit less agile and responsive compared to smaller diameter tires, and may be a bit heavier.

In conclusion, there’s no universally “better” size among these. The best tire size for you depends on your specific needs, the type of bike you have, and the type of riding you plan to do. At Hartex Rubber, we offer a range of sizes to suit all types of riders and bikes.

Working Across Sizes: The Versatility of Bicycle Inner Tubes

Bicycle inner tubes are designed to be versatile and flexible. They can work across a range of tire sizes because they can expand and contract to fill the space inside the tire.

For example, an inner tube labelled 700 x 18-23c can fit a range of tire widths from 18 to 23mm (in the ETRTO system) or equivalent sizes in the British or French systems.

The ‘c’ denotes a width classification in the French system, where ‘a’ is narrow, ‘b’ is mid-range, and ‘c’ is wide.

Effects of Inner Tube and Tire Width Mismatch

- Narrow Tubes in Wide Tires: A narrow tube in a wide tire might need to stretch more than usual to fill the space. This could make the tube thinner and more prone to punctures.

- Wide Tubes in Narrow Tires: Conversely, a wide tube in a narrow tire might not have enough space to fully expand. This could result in folds in the tube, which can cause uneven wear and increase the risk of a puncture.

The important takeaway is to aim for compatibility between your inner tube and tire sizes for the best riding experience and longevity of your products. Always check the size specifications of both your tires and tubes before making a purchase.

We at Hartex Rubber are committed to providing high-quality, durable bicycle tires and inner tubes, manufactured to fit a broad range of sizes. We ensure that all our products meet the highest standards, providing you with a smooth, safe, and enjoyable ride.

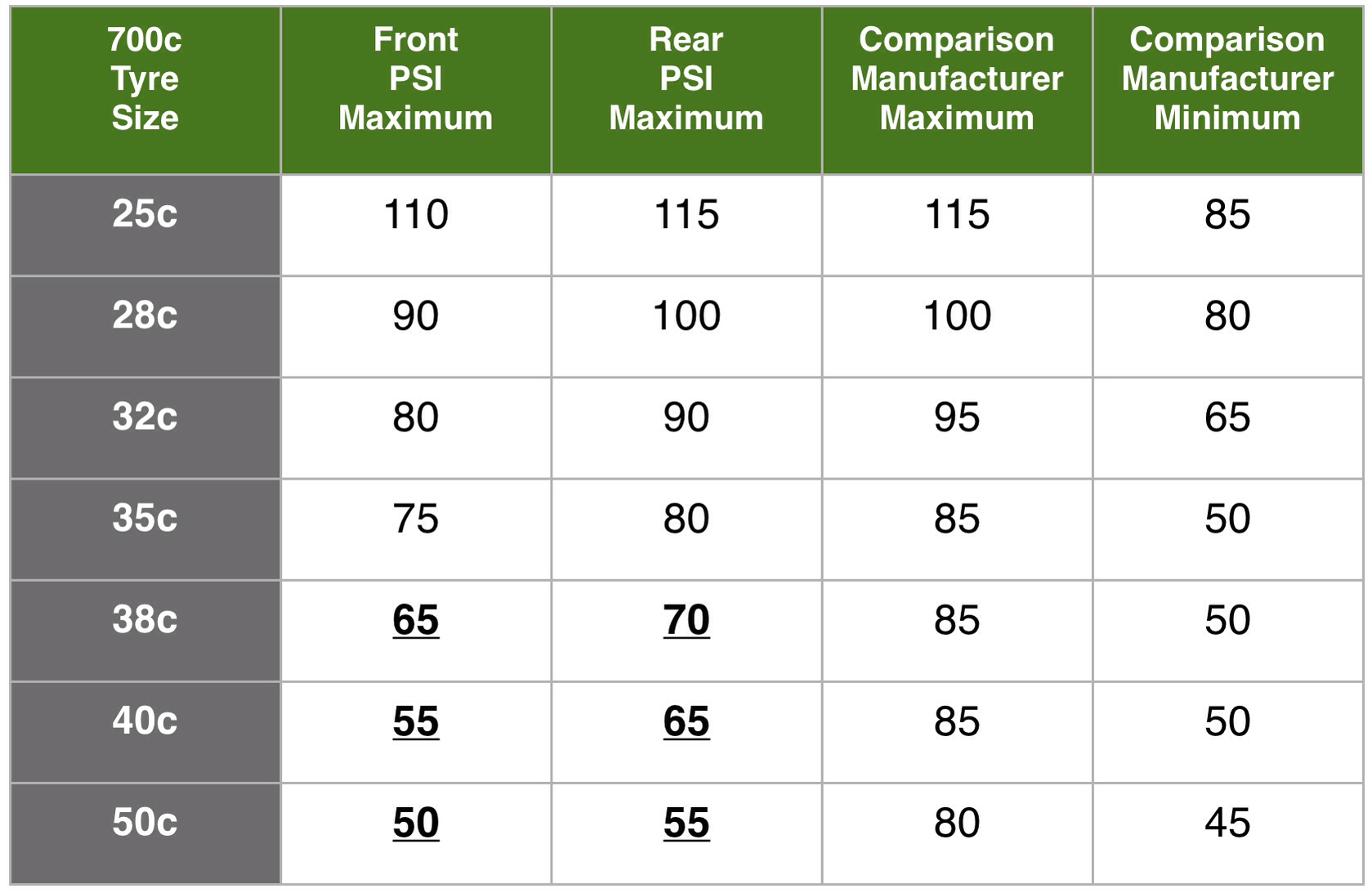

TYRE PRESSURE

What is the correct tire pressure for bicycle tires and how does it impact performance and comfort?

The correct tire pressure for bicycle tires varies widely depending on factors such as the type of bike, the weight of the rider, the tire size and design, and the riding conditions.

Road bikes, with their narrow tires, typically require a higher pressure compared to mountain bikes or hybrid bikes with wider tires. For example, road bike tires might need anywhere from 80 to 130 PSI (Pounds per Square Inch), while mountain bikes might range from 30 to 50 PSI, and hybrids somewhere in between.

Your weight also influences the correct tire pressure. Heavier riders generally require more tire pressure than lighter riders. Some manufacturers provide charts that suggest tire pressure based on rider weight and tire size.

The riding conditions matter as well. For off-road or trail riding, a lower tire pressure provides better traction and shock absorption. On smooth pavement, a higher tire pressure can make your ride faster and more efficient.

Here’s how tire pressure impacts performance and comfort:

- Rolling Resistance: Higher tire pressure reduces the tire's rolling resistance, which can make your ride faster and more efficient on smooth surfaces. Lower tire pressures, while increasing rolling resistance, can provide better traction and control on uneven surfaces.

- Comfort: Lower tire pressure increases the tire’s ability to absorb shocks from bumps and rough surfaces, which can make your ride more comfortable. Higher pressures can result in a harsher ride.

- Traction: Lower tire pressure can increase the tire's footprint and improve traction, especially on loose or slippery surfaces.

- Flat Protection: Higher tire pressure can help prevent flats by reducing the chance of pinch flats, where the tube gets pinched between the tire and rim. However, too much pressure can make the tire more susceptible to punctures.

Remember, these are general principles, and the ideal tire pressure can vary based on many factors. It’s essential to experiment a bit to find what works best for you and your specific situation. As a starting point, look for the recommended tire pressure range printed on the side of your tire.

Always use a good quality bicycle pump with a pressure gauge to ensure you’re inflating your tires to the correct pressure. And check your tire pressure regularly, as it can decrease over time due to temperature changes, tiny leaks, or natural permeation of air through the tube.

tYPES OF BICYCLE TYRES AND TUBES

Provide a step-by-step guide on how to install bicycle inner tubes, bicycle tube-type tires as well as bicycle tubeless tires. What are the pitfalls one should avoid to prevent a faulty setup or one that might damage the tire and/or tube?

Here’s a step-by-step guide on how to install bicycle inner tubes, tube-type tires, and tubeless tires.

Installing Bicycle Inner Tubes and Tube-Type Tires:

1. Inspect the Rim: Look for any damage on the rim tape that could puncture the tube. Also, remove any debris from the rim.

2. Check the Tire: Inspect your tire for any cuts or embedded objects like glass or stones.

3. Align the Tire: Align the tire and tube with the rim. Make sure to line up the tire's inflation valve with the rim's valve hole.

4. Insert the Tube: Partially inflate the tube just enough that it takes shape but is not tight. Insert the valve through the rim valve hole, then gently nestle the tube into the tire.

5. Mount the Tire: Starting opposite the valve, begin to press one tire bead over the rim wall. Work your way around to the valve. Repeat this process with the other bead.

6. Check Alignment: Verify that the tube isn't pinched between the tire and the rim, which can lead to a puncture.

7. Inflate the Tire: Inflate the tire to the pressure recommended by the tire manufacturer, typically written on the tire sidewall.

Installing Tubeless Tires:

1. Inspect and Clean the Rim: Make sure the rim is clean and undamaged. If the rim is not tubeless-ready, you'll need to apply tubeless rim tape.

2. Install the Valve: Push the valve through the rim's valve hole and tighten the lockring.

3. Mount One Side of the Tire: Mount one bead of the tire onto the rim, just like you would with a tube-type tire.

4. Apply Sealant: Pour the recommended amount of tubeless sealant into the tire.

5. Mount the Other Side of the Tire: Work the other bead onto the rim. This can be harder than with a tube-type tire as tubeless tires fit more snugly.

6. Inflate the Tire: Use a high-volume pump or compressor to inflate the tire. You should hear a series of pops as the tire bead seats against the rim.

7. Check the Seal: Spin and shake the wheel to distribute the sealant and check the tire for any leaks.

Pitfalls to Avoid:

1. Not Checking the Rim and Tire: Always inspect the rim and tire for damage or debris that could puncture the tube or prevent a good seal.

2. Incorrect Alignment: Misalignment can cause the tube to be pinched between the tire and rim or prevent the tire bead from seating correctly.

3. Overinflation: Don't inflate the tire beyond the manufacturer's recommended pressure.

4. Skipping Sealant for Tubeless: For tubeless setups, always use sealant to help the tire bead seat correctly and to seal any small leaks.

5. Not Checking the Fit: Always double-check the tire and tube installation before riding. If something doesn't look right, it's better to fix it before it causes a problem on the road or trail.

Remember, installing tires and tubes can be challenging, especially if you're new to it. Don't hesitate to seek help from a knowledgeable friend or your local bike shop.

tips and guidelines for BICYCLE TYRES AND TUBES

Provide tips and guidelines on how to take care of bicycle tires and tubes to prolong their life and maintain optimal performance.

Proper care and maintenance of your bicycle tires and inner tubes can significantly prolong their lifespan and enhance your cycling experience. Here are some essential guidelines and tips:

- Regular Inspections: Check your tires before every ride for embedded glass, sharp rocks, or other debris. These can work their way through the tire over time and cause a puncture.

- Tire Pressure: Check your tire pressure regularly, preferably before each ride. Proper inflation can prevent unnecessary wear, provide a better ride quality, and prevent flats. Make sure to inflate your tires within the range recommended on the tire sidewall.

- Clean Regularly: Clean the tires with warm water and mild soap after muddy or dirty rides. This will help identify any potential issues like cuts or wear spots and can prevent the build-up of materials that could damage the tire.

- Rotate Tires: If you notice that one tire is wearing out faster than the other, usually the rear, consider swapping the tires. This can help ensure that they wear out more evenly and increase the overall lifespan.

- Storage: When you're not riding your bike, try to store it in a dry, cool place out of direct sunlight. UV rays can degrade the rubber over time.

- Replace Tubes With Tires: When it's time to replace your tires, consider replacing your tubes as well. Tubes can wear out and become porous over time, so a new tire with an old tube can lead to flats.

- Tire Sealant: If you're using tubeless tires, remember that the sealant inside them dries out over time. Check and replenish your tire sealant every 2-6 months, depending on your climate and the specific sealant you're using.

- Avoid Skidding: Try to avoid skidding, which wears out tires prematurely. Learn to brake effectively by applying both brakes evenly, and remember that your front brake generally provides the most stopping power.

By adhering to these guidelines, you can extend the life of your bicycle tires and tubes, improve your cycling experience, and decrease the chances of experiencing a flat tire during your rides.

FAQ's about Bicycle Tires and Rims

Guide: Tire Sizes and Rim Width Compatibility

Please note that this is a general guideline and you should always refer to the manufacturer’s specifications for the most accurate information.

|

Rim Width (Inner) (mm) |

Minimum Tire Width (mm) |

Maximum Tire Width (mm) |

| 13-15 | 18 | 25 |

| 15-17 | 23 | 32 |

| 17-19 | 25 | 50 |

| 19-21 | 28 | 54 |

| 21-23 | 30 | 58 |

| 23-25 | 32 | 62 |

This guide is useful for understanding what range of tire widths you can safely use on your specific rims. However, always remember to check if there’s enough clearance in your bike’s frame to accommodate the chosen tire width.

At Hartex Rubber, we are always available to answer any queries or concerns you might have about our products. Ensuring the right fit for your bicycle tires and rims is crucial for the performance and safety of your bike, and we’re here to help guide you through that process.

The width of a bicycle tire is typically consistent with its labeled size, but there can be slight variations based on the specific model and manufacturer. It’s also important to note that the tire’s width can appear slightly different depending on the width of the rim it’s mounted on. For safety and optimal performance, it’s recommended to use a tire width that’s compatible with the width of your bike’s rims.

Yes, you can generally use a wider tire on your current rim, as long as it falls within the rim’s allowable range. However, going too wide can affect the tire’s shape, performance, and the bike’s handling. A tire that’s too wide can also have clearance issues with your bike’s frame and components.

Yes, as long as the tire’s width is within the rim’s allowable range. However, a tire that’s too narrow can lead to a harsh ride and increased risk of pinch flats.

frequently asked questions

The correct tire pressure varies depending on the type of bike, the weight of the rider, and the riding conditions. Look for the recommended tire pressure range printed on the side of your tire.

The lifespan of a tire or tube can depend on a variety of factors, including the type of tire, riding conditions, and how well they’re maintained. However, as a general rule, we recommend inspecting your tires for wear before every ride, and consider replacing road bike tires every 1,500-3,500 kilometres, or sooner if they’re damaged.

Clincher tires are the most common type of bicycle tires and use a separate inner tube. Tubular tires, or “tubs”, are a type of tire where the tube is sewn into the tire. These are often used in racing due to their weight and rolling benefits. Tubeless tires don’t require an inner tube and instead form an airtight seal against the rim.

The most obvious sign of a puncture is a flat tire or rapid loss of air pressure. You may also hear a hissing sound when the tire is punctured.

We recommend checking your tire pressure before every ride. Air can leak out of the tire naturally, and riding with too little tire pressure can lead to flats and can damage your rims.

A higher TPI means that the tire casing is made up of many thin threads, which often results in a lighter tire with better flexibility and improved comfort. However, a tire with lower TPI may be more resistant to punctures and wear.

All tires lose air over time, but tubeless tires can lose air a bit faster, especially when they’re new or in cooler temperatures. If your tire is losing air rapidly, make sure the bead is fully seated and check the sealant levels.

Punctured tubes can often be repaired with a patch kit. Remove the tube from the tire, locate the puncture, roughen the area around the puncture with the sandpaper provided, apply the glue, then apply the patch.

Most punctures are caused by sharp objects like thorns, glass, or metal shards. However, you can also get punctures from hitting potholes or curbs if your tires are underinflated.

Bicycle tire size is usually represented with two numbers, such as 700×23. The first number is the approximate outer diameter of the tire in millimeters. The second number is the width of the tire in millimeters.